Contact ISC Companies for Thomson Industries High-Load Ball Screws

As an authorized distributor of Thomson Industries and Altra Industrial Motion—who acquired Thomson in 2018—ISC Companies can supply the full line of Thomson linear motion products, including their high-load ball screw that was introduced in 2019.

As an authorized distributor of Thomson Industries and Altra Industrial Motion—who acquired Thomson in 2018—ISC Companies can supply the full line of Thomson linear motion products, including their high-load ball screw that was introduced in 2019.

Thomson high-load ball screws can handle more than double the load capacity or provide 10x the service life when compared to standard ball screws at equivalent performance points. They are available with up to 15 m screw lengths and with single or double nuts. They come in standard sizes up to 160 mm in diameter with up to 1,440 kN of dynamic load capacity. Preloading options are available upon request, and Thomson will customize the ball screw to meet customer-specific applications. They provide smooth, quiet motion at higher speeds over a longer life. Lead accuracy is up to 12 μm/300 mm.

Features & Highlights

- Increased capacity for high-load applications at high speeds and long lifetimes

- More economical solution vs. roller screws

- Lead accuracy of up to 12 μm/300 mm

- Compact, simple design allows for downsizing, less weight

- Optimized ball nut design for maximizing load capacity

- Available with up to 15 m screw length and with single or double nuts

- Multiple preloading options available

- Smooth, quiet motion

Thomson high-load ball screws provide maximum load capacity and longer life in a compact envelope!

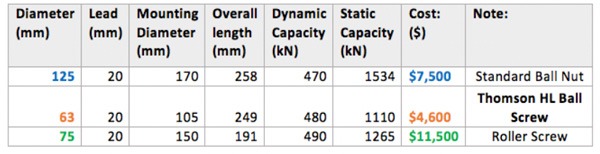

The table below illustrates the advantage of a high-load ball screw in an application that requires a minimum of 470 kN of load capacity. A standard configuration ball screw can provide a solution but would have twice the diameter and cost 63% more. A roller screw is also capable but has a nut that is close to 50% larger and would cost 150% the price of the comparable high-load ball screw.

Made for the Most Demanding Industrial Applications

High-load ball screws are ideal for demanding motion control applications such as injection molding, pressing, and large fabrication equipment. They minimize replacement and maintenance costs significantly for the application, which provides an ideal opportunity to replace roller screws or hydraulic systems in applications with axes that require accurate and safe movement of heavy loads, long and reliable life, and minimum maintenance.

Ideal applications include:

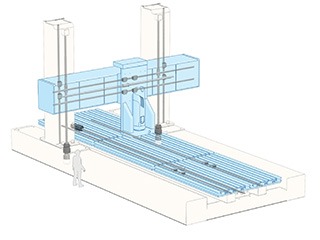

- Large fabrication equipment, including mills, water jets, plasma cutters and automatic welders, which must control motion on horizontal and vertical axes.

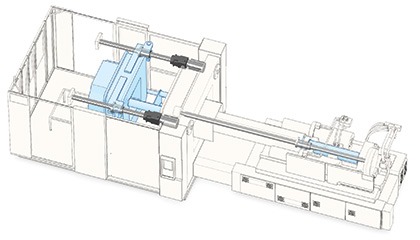

- Injection molding and metal fabrication machines, where ball screws can handle high loads in a short stroke with high precision.

- Metal pressing and forming applications, including rivet presses, servo presses, tube bending, metal sheet bending, test rigs and straightening machines.

- A wide variety of other demanding applications, including machine tools, lifting devices, large valves and high-load actuators.

Milling Machine Application

Injection Molding Application

Learn more about Thomson High-Load Ball Screws in this brochure. For more information about the products we offer from Thomson Industries, visit our dedicated brand page.

To get a product quote, contact us by phone 763-559-0033, by email [email protected], or fill out our online contact form.

You must be logged in to post a comment.