ISC Automation is an authorized distributor and systems integrator of the NACHI Robotic Systems (nachirobotics.com). For more information or for a product/support quote, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

ISC Automation is an authorized distributor and systems integrator of the NACHI Robotic Systems (nachirobotics.com). For more information or for a product/support quote, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

NACHI developed their first high-performance industrial robots in the 1960’s, and proved their high innovative abilities in the field of automation. Since then, NACHI has continuously increased its range of industrial robots for all application areas. Whether loading/unloading of machine tools and injection molders or spot and seam welding in the automotive and steel construction industries, picking, packaging, and palletizing of all kinds of components, as well as positioning and assembling small components in electronics manufacturing. The NACHI Robotic Systems, Inc. North American headquarters is in Novi, MI.

Compact Handling Robots

The MZ Series high speed/high precision compact robots are available in 5- and 6-axes models that protect against dust and water in multiple installation orientations. The internal wire routing for the tooling significantly increases cabling reliability, and also reduces the footprint, enabling operation in narrow spaces. A wide operating range improves productivity and high spec/ performance applications such as vision sensor are available. Meets various automation needs: machine loading, picking, loading and assembling, deburring/polishing, sealing, and more.

MZ01

MZ01

MZ07 / MZ07L

MZ07 / MZ07L

MZ25

MZ25

MZ03EL

MZ03EL

MZ10

MZ10

MZ04

MZ04

MZ12

MZ12

CZ10

Collaborative Robot

The 6-axes CZ10 slim arm collaborative robot has several operator-friendly functions and structures like rounded arms and gaps between joints. Safety fences are not required, which makes it easier to install a robot with various applications, such as picking, assembling support, machine loading, and more.

Dual Safety

- Functional safety: Stops when detecting contact with person.

- Intrinsic safety: Designed not to pinch a person.

SCARA Robots

The 4-axes EC06 Series are simple structure robots that are ideal for high-speed and high-precision assembling and handling applications. The tip axis is a hollow structure for easy routing of tube and wire from the robot to the tool.

Wing Slicer Robots

The EZ Series wing slicer robots are horizontally-articulated and equipped with a space-saving vertical first axis. They have a high speed, high accuracy structure that is excellent for applications such as assembly and handling. Cable routing is simplified by the hollow construction through the end of the wrist. The internal wire routing for the tooling significantly increases cable reliability. The wing slicer family includes multiple models (EZ02 6-axes, EZ03 4-axes) with varying reach and payload to support a variety of equipment operations.

EC06

EC06

EZ02

EZ02

EZ03

EZ03

Medium Duty Handling Robots

The6-axes MC Series are powerful, compact, multi-purpose robots ideally suited for a variety of production environments. Models are dust-proof and moisture-resistant with outstanding performance and a full range of functions to handle a variety of applications.

The MR Series robots are designed to handle complex motions with a 7-axes, flexible motion arm and programmable pose. The compact robot arm greatly reduces the amount of space needed for installation.

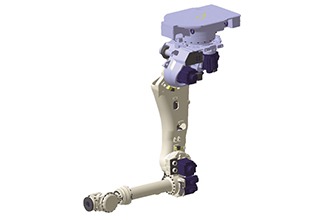

The 7-axes ST210TP press operation handling robot has a rigid design with vibration dampening, giving this robot its great speed. The specialized press arm attachment allows for a much larger reach that can be used to move parts horizontally at high speeds.

MC20 / MC10L

MC20 / MC10L

MC35 / MC50

MC35 / MC50

MR35 / MR50

MR35 / MR50

MC10S

MC10S

MC70

MC70

ST210TP

ST210TP

MC12S

MC12S

MR20 / MR20L

MR20 / MR20L

Super Heavy Loader Robots

The 6-axes MC Heavy Loader Series have high wrist torque and a large operating envelope for heavy loading capabilities. Tool cables and hoses routed inside the hollow arm extends the working life.

The 6-axes SC Heavy Loader robots, with a large load capacity and long reach, are excellent for jobs that require heavy lifting. Their large vertical stroke allows more flexible production lines by replacing conventional specialized machinery, such as auto body lifters with robots.

MC280L / MC350

MC280L / MC350

MC700

MC700

MC400L

MC400L

MC1000DL

MC1000DL

MC600

MC600

SC700DL

SC700DL

Palletizing Robots

The 7-axes LP Series of specialized palletizing robots do large movements quickly. They can stack products such as cardboard boxes, or products in bags, such as foodstuffs or chemicals, onto pallets at high speeds. Loaded with palletizing functions, they can handle a wide variety of stacking patterns.

The 5- or 6-axes MC Series heavy loader palletizing robots have enough lifting power to handle jobs loading and stacking heavy goods such as beverages, bricks, plastic resins, concrete, and more.

LP130 / LP130F / LP180 / LP210

LP130 / LP130F / LP180 / LP210

MC470P

MC470P

MC500P

MC500P

Clean Room Robots

These robots suppress the dust created by arm movements and are designed to be used in clean rooms.

The 6-axes SC400LC clean room loading robot has an articulated construction with excellent flexibility and a long reach, making it an excellent robot for a variety of loading work in large glass substrate production processes.

The 6-axes ST-C Series is vertically-articulated and handles heavy loads with ISO class 6 clean room compatibility for operating in clean room environments.

SC400LC

SC400LC

ST133CF / ST166CF / ST210CF

ST133CF / ST166CF / ST210CF

Spot Welding Robots

Welding robots are the central element of automobile production. The performance, functionality, and reliability of the NACHI lineup of spot welding robots are supporting the world of manufacturing.

The 6-axes SRA-H Series spot welding robots have a hollow arm to fully enclose cables and hoses for the welding gun, which improves cable reliability and improves the rate of operation. Its light weight, highly rigid design allows for high acceleration with minimum vibration. The high speed of all axes minimizes movement times, improving manufacturing productivity.

The 6-axes SRA Series spot welding robots are ultra-fast due to their higher speed and vibration damping properties. When compared to previous models, the SRA Series can shorten cycle times by 30%, greatly improving productivity. Design improvements include weight reduction, higher rigidity, and faster controls. With the latest in motor drive controls, power consumption is reduced by 15%, lowering the environmental impact.

SRA100HS

SRA100HS

SRA133H

SRA133H

SRA210H

SRA210H

SRA100J

SRA100J

SRA166 / SRA210 / SRA240 / SRA250

SRA166 / SRA210 / SRA240 / SRA250

SRA166HT / SRA210HT

SRA166HT / SRA210HT

SRA100HB

SRA100HB

SRA133HL

SRA133HL

SRA220H

SRA220H

SRA100B

SRA100B

SRA120EL / SRA133L / SRA166L

SRA120EL / SRA133L / SRA166L

SRA210V

SRA210V

SRA100H

SRA100H

SRA166H

SRA166H

SRA220HV

SRA220HV

SRA100

SRA100

SRA166T / SRA166TL / SRA210T

SRA166T / SRA166TL / SRA210T

Controllers

NACHI intelligent controllers based on Windows make robots and additional axes easy to operate by using the teach pendant. Vision, force sensors, and networks are managed in one place.

FD18 Controller

FD18 Controller

CFDL Controller (for EZ Series)

CFDL Controller (for EZ Series)

FD11 Controller

FD11 Controller

CFD Controller (for MZ Series)

CFD Controller (for MZ Series)

You must be logged in to post a comment.