ISC Companies Offers Revolutionary ABB Ability Smart Sensors

As an authorized distributor of ABB (Baldor, Dodge), ISC Companies is now offering ABB Ability Smart Sensors. For more information or for a quote, contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

The ABB Ability™ Smart Sensor converts traditional components like motors, pumps, and mounted bearings into smart, wirelessly connected devices. The sensor measures key parameters from the surface of the equipment, which can be used to gain important information about condition and performance. Users can use that information to identify inefficiencies within their system and reduce risks related to operation and maintenance. Maintenance can now be planned according to actual needs rather than based on generic schedules. This extends the lifetime of equipment, cuts maintenance costs, and reduces/prevents unplanned downtime due to breakdowns.

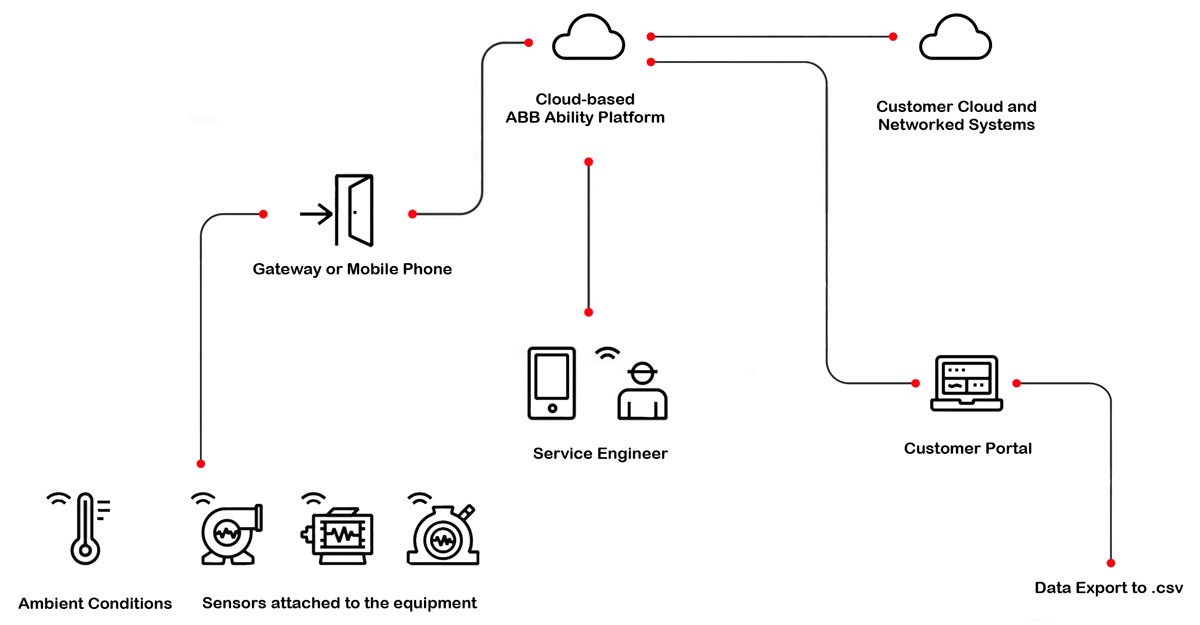

ABB Ability connects you to the power of the Industrial Internet of Things (IIoT). ABB offers a unique digital advantage by combining connectivity and data analytics with our expertise to make your operations efficient, predictable, and safe.

ABB Ability Smart Sensor for Hazardous Locations

The high-performance ABB Ability Smart Sensor for hazardous areas monitors the health and performance of rotating machines operating in explosive environments. It is ATEX, IECEx, and NEC 500 certified.

Sensor Installation and Retrofitting

ABB mechanical products come sensor ready with drilled, threaded, and plugged installation holes. The sensor is installed by removing the plug and threading the sensor into the provided receptacle.

For easy installation in the field, an adapter is available for retrofitting existing Dodge mechanical products with an ABB Ability Smart Sensor. The gearing adapters replace one of several oil fill plugs with a blind plug. The sensor adapter for bearings replaces the standard grease fitting in the housing, allows for easy installation of the sensor, and provides a grease port for continued hand lubrication of the bearing.

ABB Ability Smart Sensor Portal

The Smart Sensor for mechanical products includes complimentary access to the ABB Ability digital platform. This portal allows you to monitor function and analyze data trends, leading to better uptime and ensuring that critical operations run smoothly and consistently.

The sensor uses Bluetooth Low Energy to wirelessly communicate information about the mechanical products operational health via your smartphone or bluetooth-gateway to a secure server. Data from the sensor can be displayed graphically on a smart phone, tablet, or the web portal. Twenty Smart Sensors can be connected to one Gateway.

ABB Ability Smart Sensor Platform App

The Smart Sensor Platform app was designed with ease in mind. It allows you to get up-to-date information on all monitored products at any time, no matter where you are. Simply download ABB Ability Smart Sensor App for iOS or Android.

ABB Ability Smart Sensor Cloud Interface

Integration of the ABB Ability Smart Sensor Cloud Interface requires that the users’ software has Internet access, supports HTTPS RESTful APIs and that the users have login credentials for the ABB AbilityTM Smart Sensor web portal.

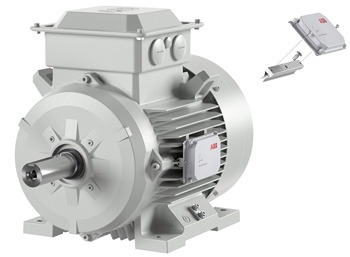

ABB Ability Smart Sensor for Motors

The Ability Smart Sensors is attached to the motor frame; no wiring or machining is needed. Using algorithms, the sensor relays information about the motor’s operation and health via a gateway or smartphone to a secure server.

Motor Health Parameters

- Overall condition

- Overall vibration (velocity rms)

- Bearing condition

- Misalignment

- Skin temperature (degrees)

ABB Ability Smart Sensor for Mechanical Products

The ABB Ability Smart Sensor for mechanical products monitors the health of Dodge mounted bearings and gear reducers (gearboxes), allowing users to reduce downtime, improve reliability, and operate more safely. The sensor gives warnings on decreasing health status, which allows you to plan maintenance before a problem occurs or the system goes down. The ability to monitor mechanical products remotely allows workers to safely get a health check without touching equipment. Trending data helps to develop patterns for monitoring performance and ability to predict replacement.

ABB Ability Smart sensor for General Machinery

The ABB Ability Smart Sensor for general machinery is used to measure and monitor temperature and vibration of general machinery applications, from fans to mechanical skids. It complements the health and performance analysis that the Smart Sensor applies to motors, mounted bearings, gearing, and pumps. Collectively, both Smart Sensors offer a much greater insight into the operations of a powertrain.

ABB Ability Smart Sensor Condition Monitoring for Pumps

The ABB Ability Smart Sensor for pumps monitors the vital operating parameters of the pump, such as vibration and temperature, to calculate pump health indicators. These indicators provide valuable information on the pump’s condition and performance. They can help to predict pump failure by detecting early signs of common operating problems, such as bearing failure, blade problems, looseness, unbalance, or overheating.

The ABB Ability Smart Sensor for pumps monitors the vital operating parameters of the pump, such as vibration and temperature, to calculate pump health indicators. These indicators provide valuable information on the pump’s condition and performance. They can help to predict pump failure by detecting early signs of common operating problems, such as bearing failure, blade problems, looseness, unbalance, or overheating.

Pumps operating in dangerous environments or hard-to-reach locations pose a risk to workplace safety and are more likely to break down due to inadequate maintenance. By monitoring and transferring the data wirelessly to the cloud, maintenance needs can be identified from a distance. This increases work safety, saves time, and improves reliability.

You must be logged in to post a comment.