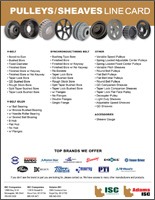

Pulleys & Sheaves

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including pulleys/sheaves. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

Industrial equipment is commonly powered by belt drives because they are flexible, relatively inexpensive, simple to install and maintain, and require a minimal amount of space. Belt-driven equipment parts are easy to obtain and replace, a fact that helps reduce downtime spent on repairs.

Industrial belt drives are used to transfer torque and aid in speed changes from one shaft to a another shaft. In all applications, the drive consists of one or more belts and a sheave/pulley relationship. Changing the diameter of the driven sheave/pulley alters the ratio and causes a change in the speed.

Drive belts are grouped into three basic classifications according to cross-sectional design: v (wedge), flat, and synchronous (timing). Each type of belt requires a different type of pulley system. V-style belts (V-Belts) match with a grooved pulley or sheave, flat style belts use a drum style pulley, and toothed belts (Timing Belts) match with a toothed pulley or sprocket.

V-Belt Pulleys/Sheaves

- Standard Pulley: have traditional dimensions, with one or multiple grooves, and mate with classic, small-engine, and hexagonal-style v-belts

- Companion Pulley: contain integral spokes that run radially on the pulley to produce a high strength-to-weight ratio advantageous to fractional horsepower pulleys.

- Idler Pulley: often used as a belt tensioner in v-belt drives and play an important part in maintaining the tension required to drive the transmission. Idler pulleys are required where the drive needs to clear obstructions or when the driven pulley does not maintain a sufficient arc of contact with the v-belt to transmit torque.

- Variable Speed Pulley: has a variable pitch that adjusts the driven RPM, often represented as a percentage. These pulleys are useful for maintaining belt tension for dynamic loads.

- Step Pulley: have two or more non-adjustable grooves with different pitches that change the speed ratio.

Construction

Pulleys are manufactured with grooves designed for a specific style and width of belt. Conventional/classical and narrow/wedge v-belts are also available in a cogged/notched style, a design feature that improves flexibility and heat dissipation; however, the corresponding pulleys do not require any design alterations to interact with the cogs/notches. Cogged v-belts are typically represented with an ‘X’ in the denomination. Pulleys for conventional/classical and narrow/wedge v-belts are typically interchangeable if the pitch widths and angles are equivalent.

- Conventional/Classical: A (0.5″), B (0.625″), C (0.875″), D (1.25″), E (1.5″)

- Fractional Horsepower (FHP): 2L (0.25″), 3L (0.375″), 4L (0.5″), 5L (0.65″)

- Narrow/Wedge: 3V (0.375″), 5V (0.625″), 8V (1.0″)

- Hexagonal/Double: AA (0.5″), BB (0.625″), CC (0.875″)

Mounting Styles

- Bored-to-Size/Finished/Fixed Bore: Bore shape and size matches mating shaft

- Set Screw: A through-hole allows a screw to be tightened against the axle

- Keyway: An offset slot ensures a close fit along the axle to transfer torque

- Weld-On: The pulley hub is welded to the axle

- Taper Bushing: A tapered hub locks around the shaft

- Clamped Hub: A split hub is tightened around the axle by the use of a clamp

Timing Belt Pulleys/Sheaves

Timing pulleys mate with same-pitch timing belts in synchronous drives. Pitch is the distance between one tooth’s center to the adjacent tooth’s center. Pitch designation can be inch- or metric-based.

Inch Pitch (ANSI)

- MXL 0.080″

- XL 0.200″

- L 0.375″

- H 0.500″

- XH 0.875″

- XXH 0.250″

Metric Pitch

- T pitch (trapezoidal) 2.5mm, 5mm, 10mm, 20mm

- AT pitch (curvilinear) 5mm, 10mm, 20mm

- GT* pitch (curvilinear) 2mm, 3mm, 5mm

- HTD* High-Torque Drive (curvilinear) 3mm, 5mm, 8mm, 14mm, 20mm

- Super-torque (curvilinear) sizes range from 2mm – 14mm

* GT and HTD are registered trademarks of Gates

Round Belt/Grooved Pulleys

Round belt pulleys are mechanical devices that transmit rotational motion around an axle. They are used to lift loads or to transmit power. The pulley accommodates a belt, cable, or rope in a groove around the circumference to guide the drive element.

Flat Belt Pulleys

Flat belt pulleys, driven by flat belts, are typically used in high-speed, low-power transmission systems. Common applications include textiles, paper making, office machines, and conveyors.

Conveyor/Drum Pulleys

Drum pulleys are used in conveyor and bulk handling applications that fall into five product categories: heavy duty, mine duty, quarry duty, extreme duty, and engineered class. In addition to category, drum pulleys are divided into four basic types: motorized, idler, spiral, and wing.

View Line Card | View All Line Cards

You must be logged in to post a comment.