Retaining Rings

Retaining Rings

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including retaining rings. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

In most installations, the inner ring of a bearing is pressed onto the shaft and the outer ring is installed with a tight push-fit in the housing bore. But, installing bearings on shafts and in housings requires a means for preventing axial displacement of the bearing. The retaining members should be large enough to contact the straight face of the bearing and the retaining component must accommodate the thrust of the bearing.

Conventional bearing installations using machined shoulders and different types of threaded fasteners, lock washers, and other devices, are bulky, expensive, and add considerably to the size, weight, and complexity of a bearing assembly. Both the shoulders and the threaded areas require machining, which can make disassembly for adjustment labor-intensive and time-consuming.

Retaining rings are an economical solution used to fasten assemblies on shafts or in housing/bores. Retaining rings are thin, circular, metal components that are stamped from a sheet or coiled from wire. They create a removable shoulder preventing components from moving out of position during operation. They are installed into a groove creating a shoulder that retains the assembly. Retaining rings are more efficient and cost-effective than traditional fasteners like screws, nuts, bolts, cotter pins, washers, etc.

Installation Considerations AXIAL vs. RADIAL

How the ring is to be installed will effect the type of ring you select. If installation is axial, (along the axis or center point of a shaft/housing), you will need an Axial Retaining Ring. If installation is radial, (along the radius of a circle), you will need a Radial Retaining Ring.

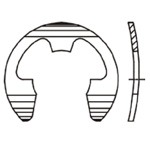

Axial Retaining Ring

Radial Retaining Ring

Conventional Retaining Ring Designs

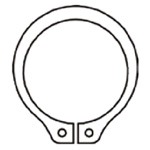

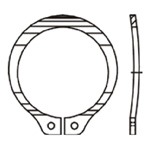

- External Rings (Snap Rings) are used to prevent bearing motion when its mounted on a shaft and are available in plated or non-plated spring steel and stainless steel.

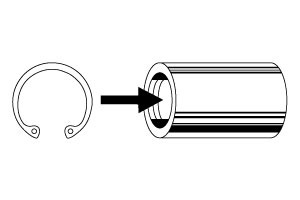

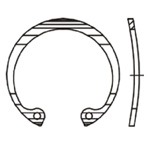

- Internal Rings (Housing Rings) are used to prevent movement of a bearing when it is used in a bore or housing and are available in plated or non-plated spring steel and stainless steel.

- Heavy-duty Rings (internal or external) exhibit the highest thrust capacity and impact resistance. They have a high protruding shoulder for maximum contact surface with the face of the bearing and can accommodate a shoulder with a large corner radius without support rings.

- Inverted Rings provide the next highest retaining shoulder. While substantially thinner than heavy-duty rings, they provide adequate shoulder height and thrust load capacity for many bearing applications. However, basic external rings have higher thrust load capacities.

- Miniature High-strength Rings are similar to heavy-duty rings but do not have protruding areas with holes, which aids installation and removal. They are assembled with tapered pins and provide a tamper-proof shoulder for holding bearings on small shafts and studs.

- Other forms/terminology include stamped, spiral (Spirolox), constant section (Hoopster), tapered section, e-clip/e-ring (radial retaining rings), clip-on, c-clips, beveled, bowed, self-locking/push-on, x-ring, crescent, wave-ring, etc.

Axial Retaining Rings

- Axially installed into machine grooves in housings/bores (internal) or on shafts (external)

- Feature lugs and lug holes used to install/remove the rings

- Make almost complete circular contact with the groove, enabling them to withstand significant thrust loads

- Provide more of a shoulder than constant section or spiral retaining rings

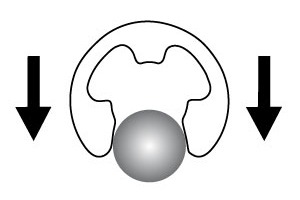

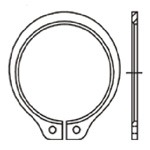

Radial Retaining Rings

- Radially installed into machined grooves on shafts (external)

- Accommodate lower thrust loads than axial retaining rings

- Don’t have lugs or lug holes, easy to install using applicators

- Do not extend as far around the circumference of the groove as their axial counterparts, thus they accommodate less force

- Economical alternative to axially assembled retaining rings

Self-Locking Retaining Rings

- Can be installed on a shaft or in a housing/bore without using a groove

- Save machining time and overall costs since a groove is not needed for installation

- Come in small sizes (some fitting shafts as small as .058″ in diameter) and can be used effectively and economically on small applications with very low thrust loads

- Most are permanent once installed and cannot be easily removed

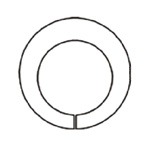

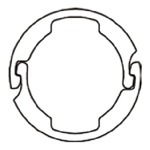

Constant Section Retaining Rings

- Axially installed into machine grooves in housing/bores (internal) or on shafts (external)

- Offer more clearance than a tapered section ring

- Accommodate less force than a tapered section ring

- Uniform material width is elliptical when installed in a groove, making three-point contact

- More difficult to install/remove

- Economical alternative to tapered section rings, depending on the application

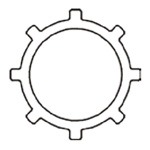

Spiral Retaining Rings

Spiral-wound retaining rings consist of two or more turns of rectangular-cross-section material having rounded edges. The material is coiled on its edge to provide a gap-less ring with 360° of retention.

There are two basic categories of spiral rings; medium-duty and heavy-duty. Both are available for internal and external applications. External rings have notches on the ring ends at the ID for removal; internal rings have notches on the OD.

- Medium-duty rings offer economy and low space and weight requirements in applications with moderate thrust loads.

- Heavy-duty rings have thicker cross-sections and fit into deeper grooves, which gives these rings about 30% more thrust load capacity than medium-duty rings.

Spiral retaining rings can be installed or removed with hand tools or with automatic equipment. A uniform radial wall height is important when radial clearance is minimal. Ring thickness can be adjusted by specifying material thickness or number of turns.

Functions of Spiral Rings

Spiral retaining rings are used for purposes other than positioning a part or keeping several components assembled. Other functions include:

- Vibration dampers in gears

- Oil dams in splines and mechanical couplings

- Back-up rings for O-rings and packings

- Oil or grease slinger rings

- Labyrinth seals in pillow block bearings

- Location stops

- Bumper impact absorbers

Assembling Spiral Rings

Spiral retaining rings may be installed manually by spreading the leaves, inserting one ring’s end into the shaft groove and working the rest of the ring around the circumference until the last turn snaps into the groove. A tapered sleeve or mandrel and a plunger are generally used for high-volume assembly. Installation fixtures should not overstress a retaining ring during assembly. An overstressed ring will not grip the groove bottom unless adequate compensation in the ring-free diameter has been made. A loss in thrust capacity could result.

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.