Roller Chain

Roller Chain

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including roller chain. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

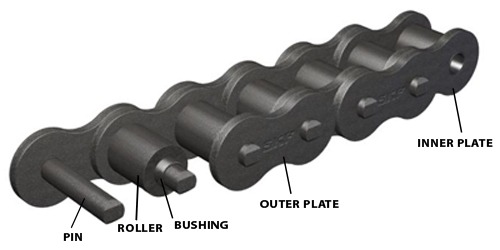

Standard single-strand roller chain, standardized by ASME, is an assembly of alternating pin links and roller links. The distance between pin centers is called the pitch. The pitch is what categorizes the size of the chain. The larger the pitch, the higher the load rating. Chains with small pitches carry smaller loads, operate more quietly, and at higher speeds. Multi-strand, small-pitch roller chains are a good solution for high-load, high-speed applications.

Every chain is connected at the ends to form a complete circle or chain loop by a master connecting link. Cotter plates or spring clips keep the connecting link’s pins from working loose.

Every chain is connected at the ends to form a complete circle or chain loop by a master connecting link. Cotter plates or spring clips keep the connecting link’s pins from working loose.

Standard strands have an even number of pitches, pin links, and roller links. A roller chain strand can be shortened by removing links and lengthened by adding whole or a half links (offset links).

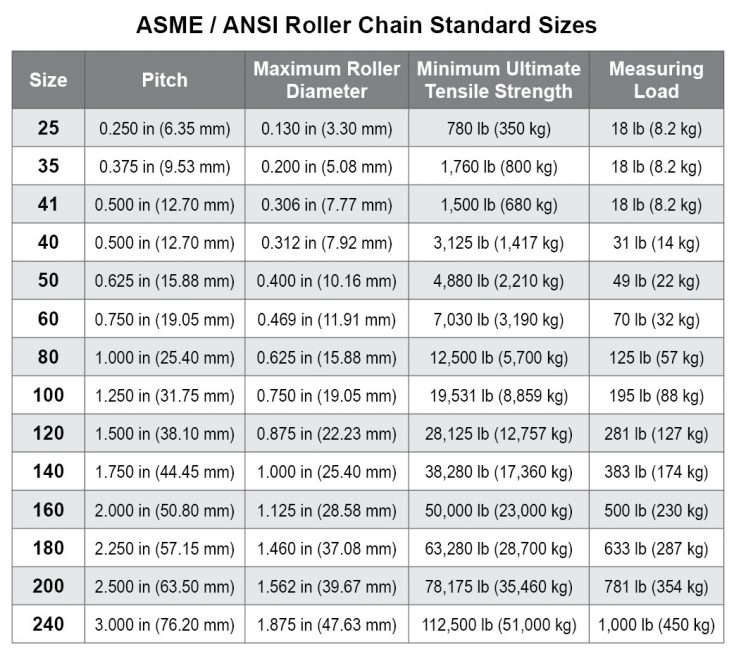

Standard roller chain is available with pitches from 1/2 to 3 inches. Chain numbers are determined by multiplying the pitch by 80 (a 1/2 inch pitch chain would be a No. 40 chain). A hyphenated suffix indicates multiple strands.

Types of Roller Chain

Self-Lube / Lube-Free

Utilize their own lube supply and are maintenance-free. They are used in applications where lubrication is prohibited due to potential contamination or where accessibility is difficult.

The most common style uses a sintered (powdered metal porous) bushing containing high-performance lubricant that coats the pin and bushing as the chain heats up. When operation is stopped, the lube is absorbed back into the bushing. Another style has special seals between the link plates.

Heavy Series and Super Series

Heavy series chains have a link plate that is the thickness of the next largest ASME chain. They are used where space and weight limitations prevent use of larger sizes. They are denoted by an “H” in chain nomenclature. Super series roller chains carry up to 60 percent greater loads with up to 40 percent greater breaking strengths.

Double Pitch

Double pitch, or extended pitch, roller chain has the same dimensions as standard chain, but the pitch is doubled. With half the number of pitches, it is lighter, less expensive, and suitable for long center distances. It is designated with a 20 preceding a standard roller chain number.

Hollow Pin

Hollow pin chain has a hole through the chain pin, where attachments can be installed. Many types of crossrods, pins, and custom attachments can be inserted at any point without removing the chain from the drive system.

Leaf

Leaf chain, also called cable chain or counter-balanced chain, consists of link plates, assembled on pins, without the use of bushings and rollers. Leaf chain is used with a sheave because there is no provision for sprocket teeth. They are widely used as forklift mast chains and counterweight chains for machine tools and elevators. Proper lubrication is important.

Silent

Silent chain, or inverted tooth chain, is quiet and flexible and is available in 3/16 in.(4.76 mm) to 2 in. (50.8 mm) pitch sizes. It consists of many links that are spaced very close together so it can carry more horsepower per inch of width. Silent chain has teeth that mesh with teeth in a silent chain sprocket. It is denoted by the prefix “SC”.

Plastic

Plastic chain is made of material that is suitable for various temperatures, chemical exposure, low-friction, and anti-static. They are best for operation in clean or food grade environments.

Specialty

Thermoforming chains, or sticker chains, are used to convey plastic film through the forming process. They use two spiked strands in parallel that pierce the film, allowing conveyance. Free flow chains allow conveyed products to accumulate. The chain travels freely underneath the accumulation.

Corrosion-Resistant

Stainless steel, nickel-plated, plastic, and zinc/nickel alloy is applied to components before assembly. They are commonly used in food processing, fertilizer, and waste management plants.

Side Bow

Side bow chains, also known as curve chain or radius chain, are available in sizes 40 through 80. This chain has extra clearance between pins, bushings, and linkplates to allow side flexing around curves or 90 degree twisting.

High-Tech Coated

Triple-protected, corrosion-resistant carbon steel chain, plates, bushings, and rivet pins; double-coated rollers and extended pins; coated and sealed with three layers. They do not replace stainless steel in very corrosive chemical or wash-down environments, but they are ideal in wet environments.

Tabletop

Has a flat surface (plate) on one side that moves material from one area to another. The plate can be part of the chain or attached to it.

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.