AC Motors

AC Motors

ISC Companies and affiliate Adams-ISC are distributors of mechanical power transmission parts including AC motors. For more information about the brands we offer and/or pricing, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

Alternating Current (AC) is what power companies transmit through the electric wires. AC travels in both directions and is used so that transformers may raise and lower the voltage. Electric generators produce low voltage electricity and transformers are used to raise the voltage for long distance transmission.

The power supplied at electrical outlets in homes is 115 V or 230 V single-phase. Single-phase means that only one voltage waveform is applied to the motor. Three-phase, 230 V, 460 V, 575 V or higher, have three wires that supply voltage waveforms, each supply electricity at different times. Three-phase is more efficient and economical and is provided to industrial sites for heavy-duty equipment with three-phase motors.

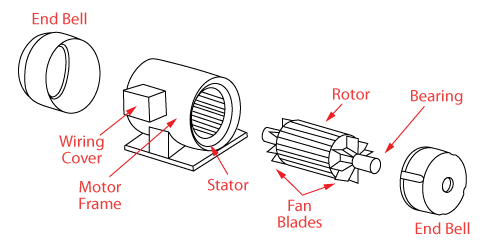

3-Phase AC Induction Motor Construction

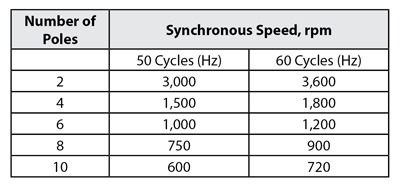

The AC motor consists of two main parts: the rotor and the stator. The stator is the outer shell and remains stationary. It has windings that transform the incoming electricity into a magnetic field. This causes the rotor to become magnetized in the opposite polarity and repel and rotate. The stator may be wound with two or more sets of windings called poles. The number of poles dictates the rpm of the motor. Standard synchronous speeds available are; 900, 1,200, 1,800, and 3,600 rpm. An induction motor turns slightly slower than a synchronous motor and takes the form of a squirrel-cage motor. The reduction in speed is called motor slip.

The rotor consists of aluminum or copper bars that run lengthwise. Electric current is induced into these bars, creating the magnetic field. This inducing of current gives the induction motor its name. The two designs for a rotor in an induction motor are squirrel-cage and wound.

- Squirrel-cage rotor (most common) is a cylinder of steel with aluminum or copper conductors.

- Wound-rotor has windings that are connected through slip rings to external resistances.

Magnetic Poles

Poles in a motor are always an even number and come in sets of two (north and south). In an AC motor, the number of poles work in conjunction with frequency to determine the synchronous speed.

Motor Slip

The difference between the synchronous speed and the actual rotor speed is termed slip. Most AC induction motors have 3 to 5 percent slip at full load. Motor plates and manufacturer’s catalogs give rpm ratings with the slip taken into account.

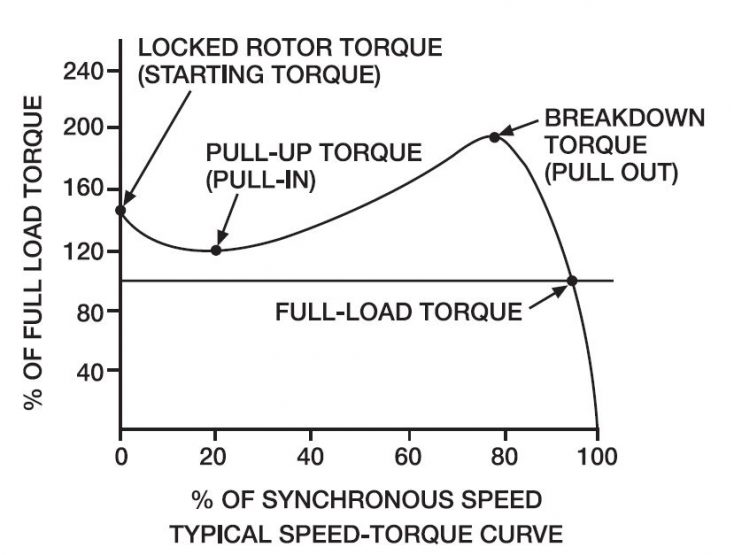

Critical Torque Levels

The speed-torque (S-T) curve displays the four torque values that are critical for motor selection and application. Locked-rotor is the torque available at zero speed for accelerating. Pull-up is the minimum available during acceleration. Breakdown torque is produced by a motor just before it stops turning due to a sudden load.

Polyphase Motors (3-Phase)

Because of the high efficiency and low cost, 3-Phase AC induction motors are the most common type of motor found in industrial applications.

3-Phase Motor Design Types

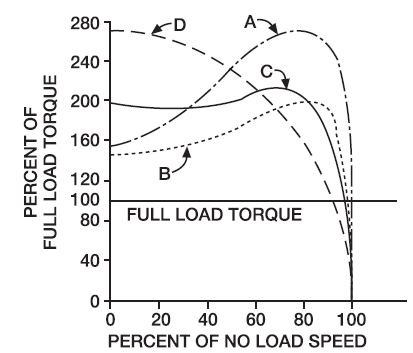

North American standards recognize four common designs of induction motors: Design A, Design B, Design C, and Design D. Designs A, B, and C have similar horsepower-frame relationships. Design D motors are larger and more costly.

Design A motors carry a higher locked-rotor current with a higher breakdown torque than Design B.

Design A motors carry a higher locked-rotor current with a higher breakdown torque than Design B.- Design B is the standard industrial duty motor. It has reasonable starting torque with moderate starting current. Typically applied to fans, blowers, pumps, compressors, and other easy-start loads.

- Design C are designed to have high starting torque. Typically applied to loaded conveyors, crushers, mixers, agitators, reciprocating compressors, displacement pumps, and other hard-start loads.

- Design D motors are installed on punch presses, shears, hoists, oil well pumps, and other high-peak-load machines. They have the most slip.

Multispeed Motors

Three-phase induction motors are also available for operation at two or more speeds. Motors of this type are single voltage only. Stator windings can be interconnected to provide a differing number of poles.

Adjustable Speed AC Drives

To meet the need for adjustable-speed operation, the motor controller (inverter) was developed. Process control and energy conservation are the primary reasons for using an adjustable speed drive.

Process control benefits when using an adjustable speed drive:

- Control acceleration, torque, and tension

- Adjust the rate of production with different operating speeds for each process

- Compensation for changing process variables

- Allows slow operation for setup purposes

- Allow accurate positioning

Single-Phase Induction Motors

The single-phase motor operates under the same principle as the polyphase motor, except that the rotating magnetic field effect generated by the stator does not exist until running rpm is reached. Since no starting torque is available, a design mechanism is included to start the motor. These are the various designations:

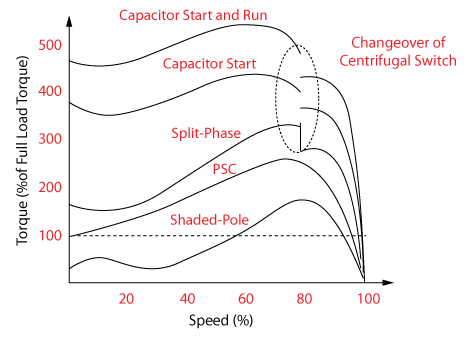

Torque-Speed Curves of Different Single-Phase Induction Motors

Shaded-pole: Have only one main winding and no start winding. This configuration causes a shift of the applied magnetic field in relationship to the rotor, creating stating torque. Applications include fans and small appliances.

Split-Phase (induction start motor): Has two sets of stator windings. The “start” windings are positioned 90 degrees to the “run” windings and shift the magnetic field of the stator, inducing starting torque. Applications include small grinders, small fans, and blowers.

Capacitor-Start: The most common single-phase motor used in industrial applications. It is a modified split-phase motor with a capacitor in series with the start winding to provide a start boost. Application include small conveyors, large blowers, pumps, and direct-drives.

Permanent-Split-Capacitor (PSC): Uses identical main and auxiliary windings with a capacitor to provide starting torque. They are the most reliable single-phase motor because no centrifugal starting switch is required. Applications include fans and pumps in HVAC and refrigeration industries.

Top Brands We Offer

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

Content on this page was created using excerpts from the Power Transmission Handbook (5th Edition), which is written and sold by the Power Transmission Distributor’s Association (PTDA).

You must be logged in to post a comment.