Ewellix – Linear Motion and Actuation Solutions

ISC Companies and Adams-ISC can supply the Ewellix linear motion products listed on this page and others found on ewellix.com. For more information or for a product quote, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

Ewellix (founded over fifty years ago as part of the SKF Group) is a global innovator and manufacturer of linear motion and actuation solutions used in industrial automation, automotive assembly, medical applications, and mobile machinery. Ewellix is headquartered in Sweden and is owned by Triton.

Ewellix (founded over fifty years ago as part of the SKF Group) is a global innovator and manufacturer of linear motion and actuation solutions used in industrial automation, automotive assembly, medical applications, and mobile machinery. Ewellix is headquartered in Sweden and is owned by Triton.

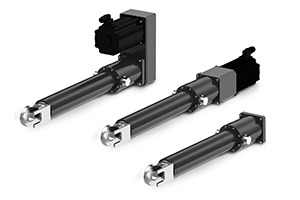

Linear Actuators

Electromechanical linear actuators enable precise, controlled, and repeatable push/pull movements in linear drive applications. Linear actuators serve as efficient, low maintenance, and environmentally-friendly alternatives to hydraulic or pneumatic types. Ewellix specializes in compact, high-quality devices, suitable for many different industry applications. A variety of stroke ranges are available, as well as actuators that can handle medium and high loads.

Matrix Series Linear Actuators

Matrix Series Linear Actuators

Ecomag Linear Actuators

Ecomag Linear Actuators

CAMT Linear Actuator

CAMT Linear Actuator

Operating Switches

Operating Switches

Runner Linear Actuator

Runner Linear Actuator

CAHB Series Linear Actuators

CAHB Series Linear Actuators

CAWD Series Linear Actuators

CAWD Series Linear Actuators

CAJA 35C Linear Actuator

CAJA 35C Linear Actuator

CAT, CAR, CAP Series Linear Actuators

CAT, CAR, CAP Series Linear Actuators

Control Units for Linear Actuators

Control Units for Linear Actuators

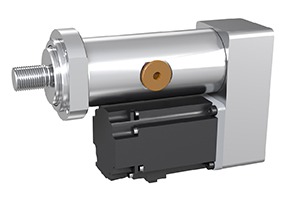

High Performance Linear Actuators

Ewellix offers a wide range of high performance electromechanical linear actuators, in a variety of designs and setups, ranging from high load capacities and fast operating speeds to systems designed for the quietest possible operation. Ewellix heavy-duty actuators offer very high positioning accuracy and controllability, enabling precise motion control with loads up to 50 tons.

CASM-25 Actuator

CASM-25 Actuator

SRSA/SVSA Actuators

SRSA/SVSA Actuators

SEMC Actuator

SEMC Actuator

CASM-32/40/63 Actuators

CASM-32/40/63 Actuators

LEMC Actuators

LEMC Actuators

CPSM Actuator

CPSM Actuator

CASM-100 Actuators

CASM-100 Actuators

CEMC Actuator

CEMC Actuator

Lifting Columns

Lifting columns (also called telescopic pillars) enable precise, controlled, and repeatable lifting movements of in linear drive applications including those with torsion and offset loads.

CPMA

CPMA

TFG

TFG

TLG

TLG

FRE

FRE

CPMB

CPMB

THG

THG

TLT

TLT

CPMT

CPMT

TLC

TLC

TXG

TXG

Ball and Roller Screws

Precision Ball Screws

- Outstanding repeatability and positioning accuracy with preload or slip prevention

- Smooth running, suitable for high vibrations or changes of direction

- Large selection of compact rolled and ground ball screws

Roller Screws

- Heavy load capacity and high axial rigidity with pre-loaded versions

- Exceptional performance in applications with frequent direction changes and high linear speed

- High positioning accuracy with excellent repeatability and reliability

Support Bearings

- Quick mounting on the shaft

- Lifelong lubrication, maintenance-free

- Rigid and accurate screw positioning

Roller Screws

Roller Screws

Precision Ball Screws

Precision Ball Screws

Support Bearings

Support Bearings

Linear Guides

Linear Ball Bearings and Shafts

- High modularity and easy to use

- Units (Single, Tandem, Quadro) available for almost every application

- Stainless steel design

- Factory pre-lubricated bearings and units

Profile Rail Guides

- Rigid, precise, and easy to assemble linear guide system

- Long service life, even with heavy loads or over long distances

- Compact design with high load capacity

- Various sizes and designs including accessories

Precision Rail Guides

- Guided systems with excellent running and repeat accuracy

- Easy adjustment of rail lengths, cage lengths, and materials

- High operational reliability and reduced downtimes

Linear Ball Bearings and Shafts

Linear Ball Bearings and Shafts

Profile Rail Guides

Profile Rail Guides

Precision Rail Guides

Precision Rail Guides

Linear Systems

Linear Slides

- Ready-to-use systems to shorten implementation and set-up times

- Virtually frictionless, precise and uniform linear movements

- Wide selection with many options

Linear Modules

- Integrated drive motor for positioning

- High and medium speed options

- Precision rails for maximum accuracy

Linear Slides

Linear Slides

Linear Modules

Linear Modules

7th Axis for Robots

LIFTKIT

Cobots are often used for palletizing but reach their limits when the pallet stack reaches a certain height. The easy-to-assemble LIFTKIT increases the reach by moving it along a vertical axis. The base of the Cobot can be raised or lowered during palletizing so that it is always in an optimum working position, improving productivity and reducing costs.

SLIDEKIT 2.0

Cobots combined with the SLIDEKIT 2.0 linear module provide a cost-effective solution to upgrade an existing assembly shop, moving from manually-handled to a fully-automatized line.

LIFTKIT

LIFTKIT

SLIDEKIT 2.0

SLIDEKIT 2.0

You must be logged in to post a comment.