PBC Linear – Actuators, Linear Bearings, Linear Guides, and Shafting

ISC Companies and Adams-ISC can supply the PBC Linear products on this page and more found on the PBC Linear website. For more information or for a product quote, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

ISC Companies and Adams-ISC can supply the PBC Linear products on this page and more found on the PBC Linear website. For more information or for a product quote, please contact us by phone 763-559-0033, by email [email protected], or by filling out our online contact form.

PBC Linear started in 1983 as Pacific Bearing Company, creating a patented and innovative solution to the common problem of failing linear ball bearings—the self-lubricating linear plain bearing. Since then, PBC has grown into a global manufacturer of linear motion technology.

Product brand names include; Hevi-Rail, Integral-V, Mini Rail, Redi-Rail, Simplicity, and Uni-Guide, SIMO (Patent Pending).

Round Shaft Technology (RST)

Simplicity® Plain Bearings

- Self-lubricating, maintenance-free, no external lubricants

- Low wear and friction, patented PTFE liner

- Wide temperature range (-400 °F/+400 °F)

- Corrosion-resistant, excels in dirty environments

- No rolling elements prevents catastrophic failure

Ball Bearings

- Polymer cage fits more balls per track than steel cage

- Built-in double seals

- Quiet operation and higher load capacity

Shafting

- Steel shafts are made of polished, case hardened steel and suitable for Simplicity plain and ball bearings

- Ceramic coated aluminum rails, non-magnetic, lightweight, and chemical resistant

- Aluminum alloy support rails available in one- or two-piece design and pre-assembled

- End-joinable for longer travel lengths

Linear Plain Bearings Simplicity

Linear Plain Bearings Simplicity

Linear Ball Bearing Pillow Blocks

Linear Ball Bearing Pillow Blocks

Linear Shafting Support Rails

Linear Shafting Support Rails

Flange Plain Bearings

Flange Plain Bearings

Flange Ball Bearings

Flange Ball Bearings

Linear Plain Bearing Pillow Blocks

Linear Plain Bearing Pillow Blocks

Roller Pillow Blocks

Roller Pillow Blocks

Precision Sleeve Linear Plain Bearings

Precision Sleeve Linear Plain Bearings

Simplicity Die Set Flange Mounts

Simplicity Die Set Flange Mounts

Square Bearings and Linear Rails

Square Bearings and Linear Rails

Linear Ball Bearings

Linear Ball Bearings

Linear Shafting

Linear Shafting

Simplicity Flange Mounts

Simplicity Flange Mounts

Flange Die Set Bushings

Flange Die Set Bushings

Cam Roller Technology (CRT)

Redi-Rail

Precision straight rails and hardened rollers are strong and lightweight, ideal for high speed and moderate load linear motion.

- High load capacities

- Patented side-adjustable preload simplifies assembly and installation

- Corrosion-resistant; excels in dirty environments

- End-joinable for longer lengths

- Gothic arch rollers with sealed double row bearings

Commercial Rail

- Cost-effective solution for automation or sliding door applications

- Speeds up to 1.5 m/s

- Three rail sizes, zinc-plated steel material

- Aluminum alloy slider with optional chrome or stainless with rollers of either 52100 steel or 44C stainless

- Rollers lubricated for life and sealed against contamination

- Left- or right-hand mountable

Heavy-Rail

Heavy-duty linear bearing system that is cost effective for medium to low precision applications. High radial and axial load capacities ensure a long and productive life. Idea for telescoping applications.

- Handles loads up to 60 tons

- Fixed or adjustable bearings

- Rail available in U or I channel design, sandblasted or lightly oiled

- Flange plate available pre-welded to bearing

- Adjustable clamp flange eliminates welding and straightening

V-Guide

- Ideal for high speed requirements, accuracy, and repeatability

- V-Guide Wheels – precision ground, dual row bearings, and internally lubricated

- Wheel Bushings – mount into V-Guide wheels for fixed or adjustable applications

- V-Rails – simple mounting and alignment, rails available in four sizes, induction hardened polished rail

Hardened Crown Rollers, Rails, and Brackets

- Simple solution for point-to-point applications

- Rolling element bearing with hex head

- Rails available up to 10′ bare steel or black powder coated

Redi-Rail

Redi-Rail

CR Commercial Rail Linear Guide

CR Commercial Rail Linear Guide

Hevi-Rail

Hevi-Rail

Hardened Crown Roller Bearings (PAC)

Hardened Crown Roller Bearings (PAC)

VW V-Guide

VW V-Guide

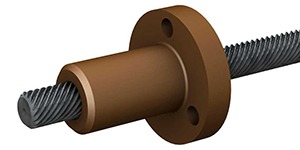

Lead Screws

PBC Linear Lead Screws are designed to work perfectly with the Constant Force™ Anti-Backlash nut, applying uniform pressure to the nut at all stages of the motion profile.

- CNC Roll Threading allows for standard accuracies of 0.003″/ft (0.001″/ft available on request)

- Proprietary process has resulted in less pitting and flanking

- 300 series stainless steel with PTFE coating

- Screw diameters of 6, 10, 12, and 16 mm and 3⁄16, ¼, ⅜, 7⁄16, and ½ inch

- Various Leads of 1, 2, 4, 5, 6, 8, 10, 12, 16, 25 mm and 0.05, 0.2, 0.25, 0.333, 0.5, 1.00 inches

- All nut styles are self-lubricating for the life of the nut

Lead Screw Motor Series

- NEMA 8, 11, 14, 17, and 23 motor sizes

- 30% more torque available

- Laser welded screw and motor providing more accurate alignment

- Larger bearings provide increased thrust capacity and longer life

- Hollow shaft concentricity ensures minimum screw runout

- Preload on bearings eliminates axial play

- Standard mounting provisions for encoder feedback

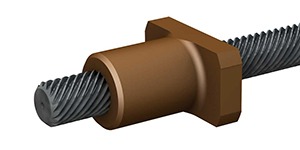

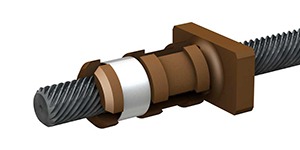

TS Triangle Nut Standard

TS Triangle Nut Standard

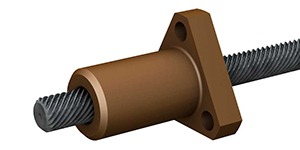

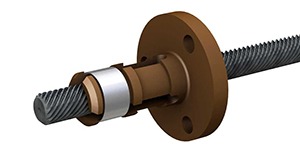

RCF Round Nut Constant Force Anti-Backlash

RCF Round Nut Constant Force Anti-Backlash

VS Rectangle Nut Standard

VS Rectangle Nut Standard

Non-captive Lead Screw Assemblies

Non-captive Lead Screw Assemblies

TCF Triangle Nut Constant Force Anti-Backlash

TCF Triangle Nut Constant Force Anti-Backlash

US Threaded Nut Standard

US Threaded Nut Standard

VCF Rectangle Nut Constant Force Anti-Backlash

VCF Rectangle Nut Constant Force Anti-Backlash

RS Round Nut Standard

RS Round Nut Standard

UCF Threaded Nut Constant Force Anti-Backlash

UCF Threaded Nut Constant Force Anti-Backlash

Lead Screw Assemblies -Motor Series

Lead Screw Assemblies -Motor Series

Actuators

SIMO®

PBC Linear has revolutionized traditional machining with the patent pending SIMO (Simultaneous Integral Milling Operation) process. The SIMO process uses synchronized cutters, eliminating built-in extrusion variances by machining all critical edges concurrently, in one pass. This ensures tight tolerances, limited variance, and a remarkably straight and repeatable surface.

SIMO actuators are built on either a low profile or tall base rail with configurable bearing and drive options that can be tailored to exceed performance requirements.

MTB

- Belt Driven

- Long travel lengths

- Fully enclosed aluminum housing

- High acceleration, speeds, and rigidity

- Male and female drive shaft configurations

- Strong, lightweight, and corrosion-resistant

ML Series

- Lead screw with multi-dovetail guided polymer nut design

- Compact profile, long travel lengths

- Available with single or dual rail blocks for increased load and moment load capacities

- High speed precision and precise repeatability

- Designed to excel in biotech, medical, and small-scale automation that requires a compact design and precise motion

Compact Series

- 300 series stainless steel lead screw with PTFE coating provides reliable linear motion in tight spaces

- Plain bearing or ball bearing

- Lead screw diameter and lead options

- Constant Force Technology nuts or standard fixed nuts

- Motor options: Integrated motor or motor mount setup

PL Series

- Ball or lead screw driven

- Sealed against contamination

- High speed cam roller design creates smooth precision guidance

- Enclosed aluminum housing with Integral-V™ raceway

MUK Series

- Heavy duty actuator providing precision and rigidity

- Incorporates two recirculating ball profile rail guideways

- Single or dual carriage options available

- Compact aluminum profile incorporates t-slots for easy sensor mounting

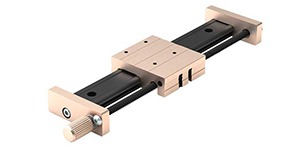

Simplicity Linear Slides

- Various NEMA motor mount sizes available

- Four pillow block assemblies

- Two steel shafts

- Two aluminum support rails

- Mounting plate

- Hand crank version available

G Uni-Guide Actuator

G Uni-Guide Actuator

MR-LS Mini Rail Actuator

MR-LS Mini Rail Actuator

MTB Linear Actuator Series

MTB Linear Actuator Series

Simplicity Linear Slides

Simplicity Linear Slides

ML Miniature Linear Actuator Series

ML Miniature Linear Actuator Series

MR-MS Mini Rail Actuator

MR-MS Mini Rail Actuator

PL Linear Actuator Series

PL Linear Actuator Series

CS Compact Series Linear Guide System

CS Compact Series Linear Guide System

UG Series Linear Motion Platform

UG Series Linear Motion Platform

MUK Linear Actuator Series

MUK Linear Actuator Series

Gliding Surface Technology

Two-piece assemblies equipped with FrelonGOLD® liner create a low friction, maintenance-free, smooth, and quiet linear motion. No metal-to-metal contact.

Uni-Guide®

- Optimal strength

- Drive option: lead screw

- T-slots for ease of installation

- Easy drop in unit—no alignment necessary

Mini-Rail®

- Requires little maintenance

- Dimensionally interchangeable with industry standard sizes

- Compact design, small footprint

- Corrosion-resistant, ideal in harsh environments

- Optional running clearances for misalignments

UGA Low Profile Uni-Guide Linear Slide

UGA Low Profile Uni-Guide Linear Slide

MR Mini-Rail Miniature Linear Guide

MR Mini-Rail Miniature Linear Guide

Uni-Guide Linear Slide System

Uni-Guide Linear Slide System

LPM Low Profile Mini-Rail Linear Guide

LPM Low Profile Mini-Rail Linear Guide

UGT Tall Profile Uni-Guide Linear Slide

UGT Tall Profile Uni-Guide Linear Slide

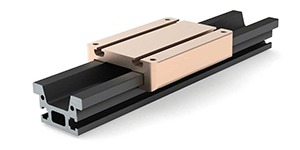

Integral-V Technology

Integral-V™ runs along a precision machined anodized aluminum rail with high-speed v-wheel cam rollers, eliminating mounting components, and cutting assembly time in half.

IVT is ideal for contaminated environments and high speed/acceleration applications. SIMO® machined for precision qualified rail surfaces, to within 0.002″. Hardened stainless steel races eliminate fasteners and reduce mounting components by 40% Handles loads up to 2,252 lbs.

IVTAAB Linear Guide

IVTAAB Linear Guide

IVTAAN Linear Guide

IVTAAN Linear Guide

IVTABK Linear Guide

IVTABK Linear Guide

IVTAAE Linear Guide

IVTAAE Linear Guide

IVTAAQ Linear Guide

IVTAAQ Linear Guide

IVTAAG Linear Guide

IVTAAG Linear Guide

IVTAAW Linear Guide

IVTAAW Linear Guide

You must be logged in to post a comment.