Specifications

| Weight | 0.06 lbs |

|---|---|

| Manufacturer | Lovejoy |

| Mfg Part Number | 68514411492 |

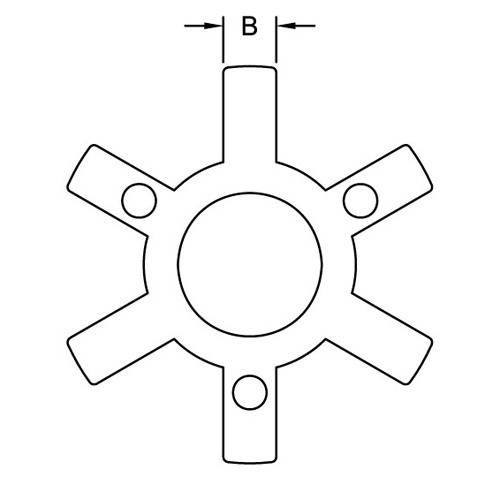

| Component Type | Spider |

| Spider Material | Nitrile Buna-N Rubber |

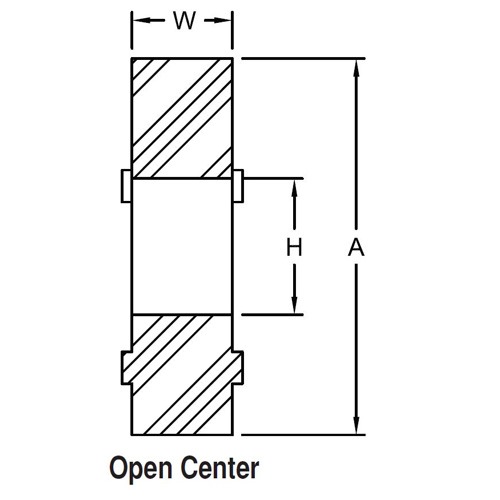

| Insert Style | Open Center |

| Color | Black |

| Series | L, AL |

| Coupling Size | 099, 100 |

| Jaw Type | Straight |

| Outside Diameter | 2.54" |

| Number of Legs | 6 |

| Leg Width | 0.43" |

| Width | 0.61" |

| Hole Size | 1.03" |

| Temperature Range | -40 to 212 °F |

| Torque Capacity | 318 in-lbs, 417 in-lbs |

| Angular Misalignment | 1° |

| Parallel Misalignment | 0.015" |

| Element Durometer | 80A |

| Maximum RPM | 7000 RPM |

| UPC | 685144114921 |